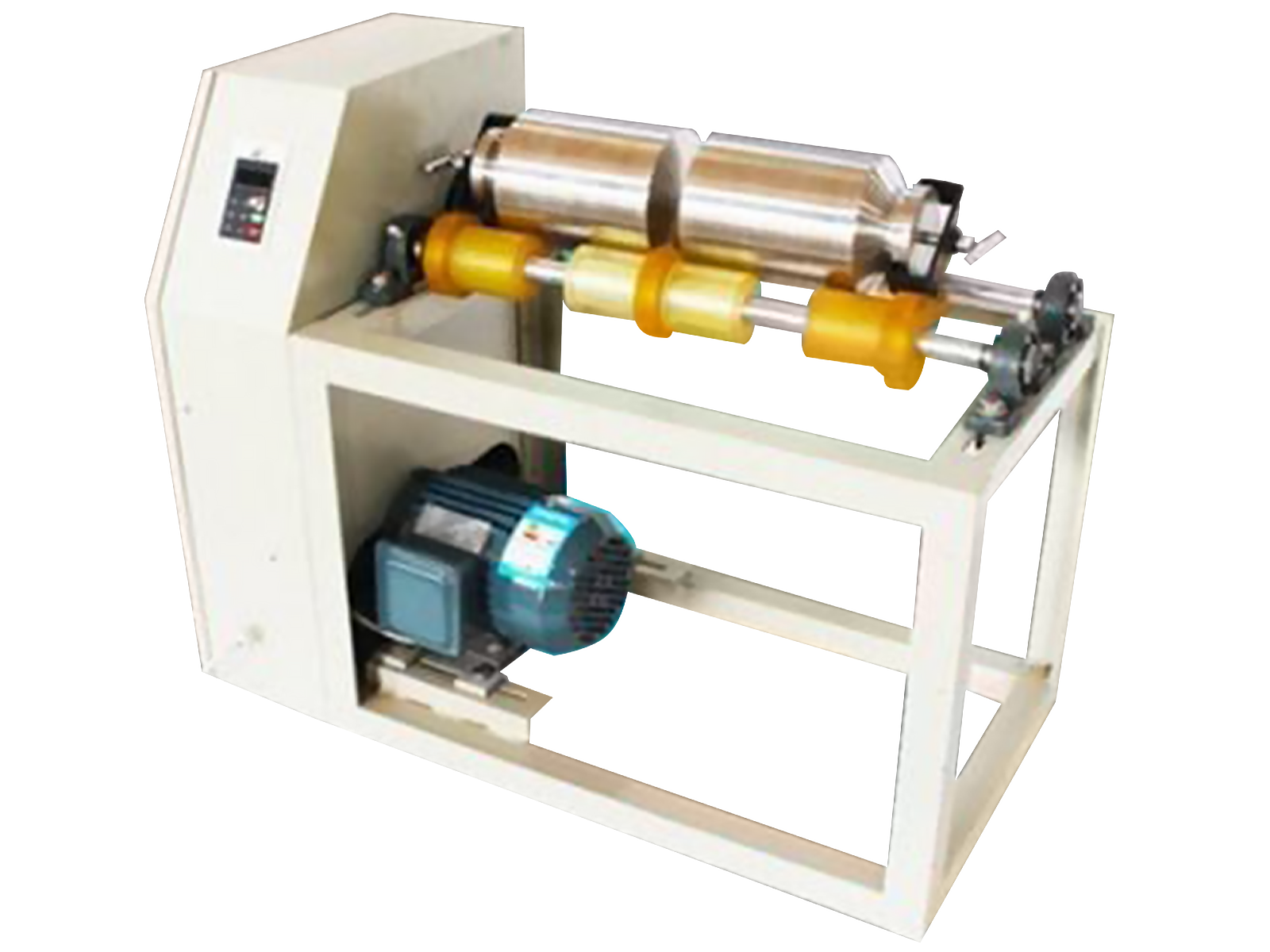

NANO PRO 4-Jar 1L Omnidirectional Planetary Ball Mill

NANOSSR offers omnidirectional planetary ball mill used for high-tech micro computer chip control. It can run alternately for positive turn and reverse turn(0-999min), and run alternately for positive turn and pause, reverse and pause, and then positive run. The omnidirectional ball milling also alleviates sample-wall sticking, which reduced maintenance cost as well as downtime. It is especially suitable for cooling or intermittent operation.

Technical Specification

|

Model |

NANO PRO 4-Jar 1L Omnidirectional Planetary Ball Mill |

|

Grinding tank volume (ml) |

50ml-250ml |

|

Material of grinding jar |

Metal material:304 stainless steel、Tungsten carbide(YG8) |

|

ceramic / corundum / alumina, zirconia, agate |

|

|

High polymer material:Nylon, polyurethane, polytetrafluoroethylene(PTFE) |

|

|

materialof grinding ball |

Stainless steel,ceramic,corundum,alumina,zirconia, agate, tungsten carbide |

|

Maximum loading per jar |

Raw material and grinding ball are not exceed2/3 of grinding jar |

|

Feeding granularity |

Friable material less than 10mm,others less than 3mm |

|

Discharging granularity |

Minimum downto0.1μm |

|

Grinding Method |

Dry/wet/ high energy alloying/vacuum (need customized) / low temperature grinding(need customized) |

|

Planetary speed |

Max Revolution 0-450r/min,Rotation0-900r/min Planetary total speed:0-3600r/min |

|

360 degree speed |

1-14RPM |

|

speed ratio(revolution:rotation) |

1:2 |

|

Adjusting speed control method |

PLC Frequency conversion control system,Touch screen control system |

|

Driving mode |

Gear drive |

|

Grinding ball ratio(the detail ratio contact customer service)The right sheet is just for reference.In fact that we are matching according to the customer requirement. |

Usuallygrinding over 800 mesh(5mm;10mm;15mm) feeding material less than 3mm |

|

Fine grinding 800-1500 mesh(3mm;5mm;10mm;)feeding material less than 1mm |

|

|

Super fine grinding over 1500 mesh(0.1~10μm)(1mm;3mm;5mm)feeding material less than 200 mesh |

|

|

Voltage |

110V |

|

Power |

0.55Kw |

|

Working method |

Two or four cans working at the same time |

|

Maximum continue working time |

72h(Timing 0-9999h) |

|

Programmed control |

The ball mill used high-tech chip control of micro computer. It can alternately of corotation and reversal(0-999min)and pause. It is especially suitable for cooling or intermittent operation. |

|

Weight |

170kg |

|

Dimension |

95*55*65 |

Our wide range of premium quality milling jars and milling media balls have excellent wear resistance and milling efficiency for powder milling, for customization please contact us.